Industrial networks & OT security for production

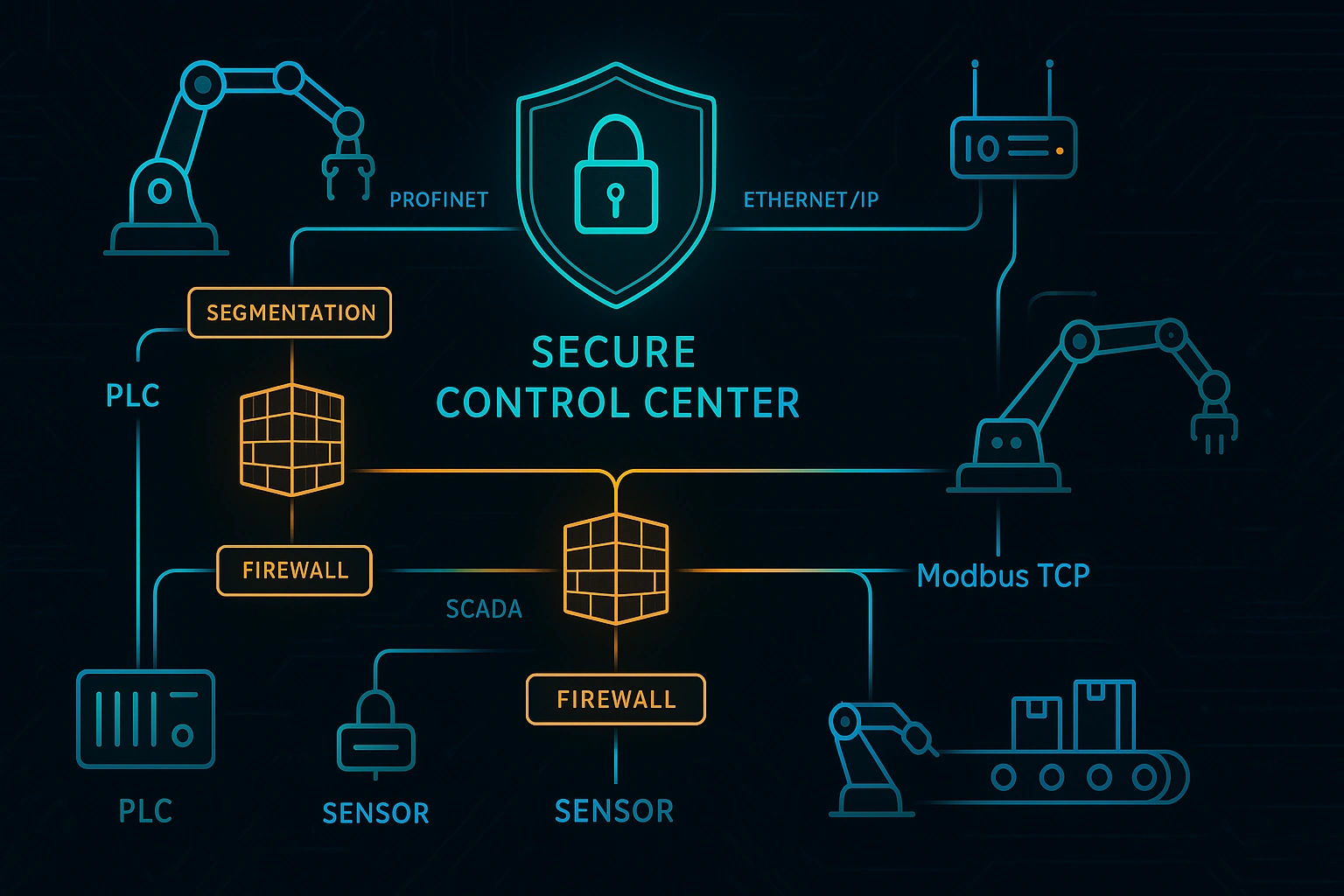

Separate segments for production lines, automation, SCADA and IT, with controlled remote access and constant monitoring.

Production & automation

When downtime hits production directly

Industrial networks have different requirements than office networks: predictable latency, stability, compatibility with old equipment, and high risks if someone makes a configuration mistake.

We clearly separate the area OT of IT, we implement strict access controls for suppliers and integrators and bring visibility into factory traffic, without disrupting production.

- Dedicated segments for production lines, SCADA and management.

- Controlled remote access for suppliers/integrators, with full audit.

- Security policies adapted to industrial protocols.

- Recovery plan and controlled change for OT equipment.

Where to apply

Production plants

Networks for automated lines, production cells and SCADA, with controlled remote access for suppliers.

Warehouses with automation

Networks for conveyors, sorters, robots and WMS, with industrial Wi-Fi and IoT segmentation.

System integrators

Common security standards for your projects so that each delivery is easy to operate for the end customer.

Frequently asked questions

Do you also intervene while the factory is in production?

Yes, but any intervention is done with a change plan, clear window and documented rollback, in agreement with the production team.

Do you work with our OT equipment suppliers?

Yes. We coordinate the implementation with existing integrators and ensure that configurations are aligned with security policies.

Can you integrate OT traffic into SIEM/SOC?

Yes, we expose relevant telemetry and logs to existing SIEM/SOC platforms, without overloading the infrastructure.